COMET — Plug-and-produce COmponents and METhods for adaptive control of industrial robots enabling cost effective, high precision manufacturing in factories of the future

Researchers: Rolf Johansson, Anders Robertsson, Björn Olofsson and Olof Sörnmo in cooperation with Dept. of Computer Science, Lund University and several academic and industrial partners.

Project Leader: Anders Robertsson

Funding: This project is financially supported by the European Union's Seventh Framework Programme FP7 under the programme "Factories of the Future", ref. #258769 COMET.

Duration: 2010-2013

Official website: COMET.

Description

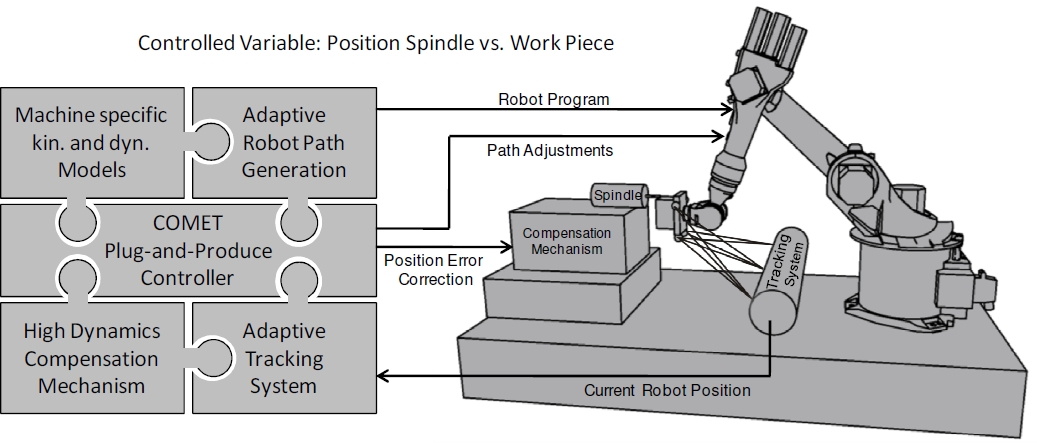

The COMET project aims at creating solutions enabling the use of industrial robots for high-end machining tasks in industry. The goal of the project is to develop a Plug-and-Produce platform, which will fulfill the needs from the manufacturing industry for cost effective, flexible and reliable manufacturing solutions. The components of the project are described by the figure:

The four pieces of the puzzle in the figure above define the different parts of the project, which also constitute the technical work packages:

- WP1: In this work package, a methodology for describing kinematic and dynamic models of an industrial robot will be developed. Those models will accurately define the static and dynamic behavior of any industrial robot, which then is represented by its unique signature.

- WP2: An integrated programming and simulation environment for adaptive robot path generation will be developed in the second work package. The path generation system will utilize the models of the robot obtained in WP1 for accurate path generation.

- WP3: The third work package is to develop an adaptive tracking system for industrial robots to detect deviations from the programmed robot path and to adaptively initiate real-time corrections via the robot controller to ensure the necessary machining accuracy.

- WP4: For high-precision machining, a high-dynamic compensation mechanism will be developed. By utilizing this mechanism, the aim is to accomplish an absolute accuracy better than 50 um in machining tasks. This is significantly below the structural capability of the robot system on its own, due to the limited stiffness and positioning accuracy of the robot.

Members

- AMRC Manufacturing Ltd, United Kingdom

- ARTIS, Germany

- BTU Cottbus, Germany

- Delcam, United Kingdom

- DemoCenter-Sipe, Italy

- Fraunhofer IPA, Germany

- Gizelis Robotics, Greece

- Lund University, Sweden

- N. Bazigos S.A., Greece

- Nikon Metrology, Belgium

- Nisaform s.r.o., Czech Republic

- SIR SpA, Italy

- TEKS, France

- University of Patras, Greece

Newsletters

References

Björn Olofsson: Topics in Machining with Industrial Robot Manipulators and Optimal Motion Control. PhD Thesis ISRN LUTFD2/TFRT--1108--SE, Department of Automatic Control, Lund University, Sweden, September 2015.

Ulrich Schneider, Björn Olofsson, Olof Sömmo, Manuel Drust, Anders Robertsson, Martin Hägele, Rolf Johansson: "Integrated approach to robotic machining with macro/micro-actuation". Robotics and Computer-Integrated Manufacturing, 30:6, pp. 636–647,2014.

Björn Olofsson: "Topics in Machining with Industrial Robots and Optimal Control of Vehicles". Licentiate Thesis ISRN LUTFD2/TFRT--3259--SE, Department of Automatic Control, Lund University, Sweden, 2013.

Olof Sömmo, Björn Olofsson, Anders Robertsson, Rolf Johansson: "Increasing Time-Efficiency and Accuracy of Robotic Machining Processes Using Model-Based Adaptive Force Control". In 10th International IFAC Symposium on Robot Control, Dubrovnik, Croatia, September 2012.

Björn Olofsson, Olof Sömmo, Ulrich Schneider, Marc Barho, Anders Robertsson, Rolf Johansson: "Increasing the Accuracy for a Piezo-Actuated Micro Manipulator for Industrial Robots using Model-Based Nonlinear Control". In 10th International IFAC Symposium on Robot Control, Dubrovnik, Croatia, September 2012.

Olof Sömmo, Björn Olofsson, Ulrich Schneider, Anders Robertsson, Rolf Johansson: "Increasing the Milling Accuracy for Industrial Robots Using a Piezo-Actuated High-Dynamic Micro Manipulator". In 2012 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Kaohsiung, Taiwan, July 2012.

Björn Olofsson, Olof Sömmo, Ulrich Schneider, Anders Robertsson, Arnold Puzik, Rolf Johansson: "Modeling and Control of a Piezo-Actuated High-Dynamic Compensation Mechanism for Industrial Robots". In IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS'2011), San Francisco, CA, USA, September 2011.

2012-08-09