ROSETTA—RObot control for Skilled ExecuTion of Tasks in natural interaction with humans; based on Autonomy, cumulative knowledge and learning

Integrated project funded under the European Union’s Seventh Framework Programme (FP7), (Ref. FP7 ICT-230902 ROSETTA)

Researchers: Rolf Johansson, Anders Robertsson, Magnus Linderoth, Andreas Stolt

Project Leader: Rolf Johansson

Official website: ROSETTA.

The ROSETTA research project develops technology for industrial robots that will not only appear more human-like, but also cooperate naturally with human workers. This project is funded by the European Union under the FP7 grant 230902.

The following 4 objectives are set forth:

- to enable robots to be used in complex tasks with high flexibility and robustness

- to ease the deployment effort to allow fast production changeover from product A to product B

- to produce an easy-to-use programming system to access ROSETTA robot functionality without the need for highly skilled robot programmers

- to provide new sensing, control and decision making methods for safe physical human-robot interaction.

Project information

ROSETTA is the acronym for a new European Large-Scale Integrating Research Project “RObot control for Skilled ExecuTion of Tasks in natural interaction with humans; based on Autonomy, cumulative knowledge and learning”. The 4-year project started March 1st, 2009, and has a total budget of 10 MEUR.

Goals

ROSETTA develops “human-centric” technology for industrial robots that will not only appear more human-like, but also cooperate with workers in ways that are safe and perceived as natural. Such robots will be programmed in an intuitive and efficient manner, making it easier to adapt them to new tasks when a production line is changed to manufacture a new product.

Key Issues

The need for such robot systems stems from analyses showing that future factories will produce more and more goods with high volumes, but with many variants and limited product lifetime. This requires a flexible manufacturing system allowing for frequent production changes. Robot systems are the automation method of choice to meet these demands, but they need the ability to adapt even more quickly to new tasks, and to obtain full production output faster than today. Also, it is mandatory to easily integrate robots into manufacturing lines with human workers, as the combination of manufacturing by humans and robots promises highest flexibility. Tasks difficult to automate will in this scenario remain the domain of humans, whereas operations with low automation threshold or high quality requirements will be performed by these robots.

Scientific/Technical Approach

The project will address the challenges by developing methods to engineer and program robot systems in ways that are more intuitive, more related to the task, and less specific to the installation. This will require robots to be able to execute tasks more autonomously, without the need for detailed description of every step, and will lead to a significant reduction in programming effort. Once programmed, the robots will use sensor-based learning to autonomously improve their abilities (“skills”) to perform the task quickly, quite like a human worker. When the operation is optimized in this way, the robot shares the knowledge of how to best perform the operation with other robots by sending the parameters over a network to a central server. Other robots do the same, which results in a quick build-up of production knowledge (“cumulative learning”).

Storing and sharing production-related data will make use of latest techniques developed for the Web 2.0, representing such data as form of “knowledge” that can be accumulated, enhanced and re-used by a population of robots.

The production scenario that involves robots and humans working side-by-side and interacting safely requires that design, control and supervision devices and methods are found for robots to be harmless, and to act in a way that humans anticipate and feel comfortable with. This involves developing human-like motion patterns, speech interaction as well as avoidance of any situation that may pose a hazard or uncomfortable situation to human workers or operators. The human-machine cooperation will be supervised by a multi-level sensor system involving different sensor types and a reasoning unit that will analyse the robot environment and give the robot instructions in real-time how to adjust to changing environments and to human presence.

Expected Impact

The engineering and production methods will make robot automation accessible for a variety of new applications, in particular where production is frequently adapted to new product lines. This will enable the European industry to increase its competitiveness by reducing production cost and by increasing production quality. A thorough understanding and modelling of the human/robot contact and interaction in a production scenario are major efforts of ROSETTA. The theoretical and experimental investigations will lead to injury risk classifications with the goal of creating future safety standards for human-robot cooperation, helping the industry to better utilise the potential of robots working in human environments.

Work Packages

| WP | Title | WP Leader |

| 1 | Knowledge and skill representation | Lund University |

| 2 | Knowledge transformation and learning | K.U. Leuven |

| 3 | Robust task execution | Lund University |

| 4 | Injury risk knowledge | Fraunhofer |

| 5 | Safe human-robot interaction control | Politecnico di Milano |

| 6 | Application and engineering principles | ABB |

| 7 | Demonstration platform for validation | ABB |

| 8 | Exploitation and dissemination | ABB |

| 9 | Management of consortium activities | ABB |

Press Releases and Articles

- http://www.abb.com/cawp/seitp202/041389533dc1819ec125761e004aa162.aspx

- http://www.abb.com/cawp/seitp202/8efe4eb3dff57d0ec125761e00290e20.aspx

- ICRA Best Automation Paper 2012: Andreas Stolt, Magnus Linderoth, Anders Robertsson and Rolf Johansson, Force Controlled Robotic Assembly without a Force Sensor

Web Sites

- ROSETTA http://www.fp7rosetta.org/

- ROSETTA at POLIMI http://merlin.elet.polimi.it/index.php?option=com_content&task=view&id=92&Itemid=40

Research in Lund @Control

Research was focused on force-controlled assembly. The main scenario was the assembly of an emergency stop button. The implementation used was based on iTaSC, instantaneous Task Specification using Constraints. Learning was applied to increase the assembly speed and adaptation was used to automatically adjust the force control parameters.

The emergency stop button used as the main scenario.

Force estimation

Two different methods for force estimation were developed, to be used in cases when there are no force sensor available. The first method was based on the joint control errors, and the second method was based on the measured motor torques. Both methods were successfully used in different assembly scenarios.

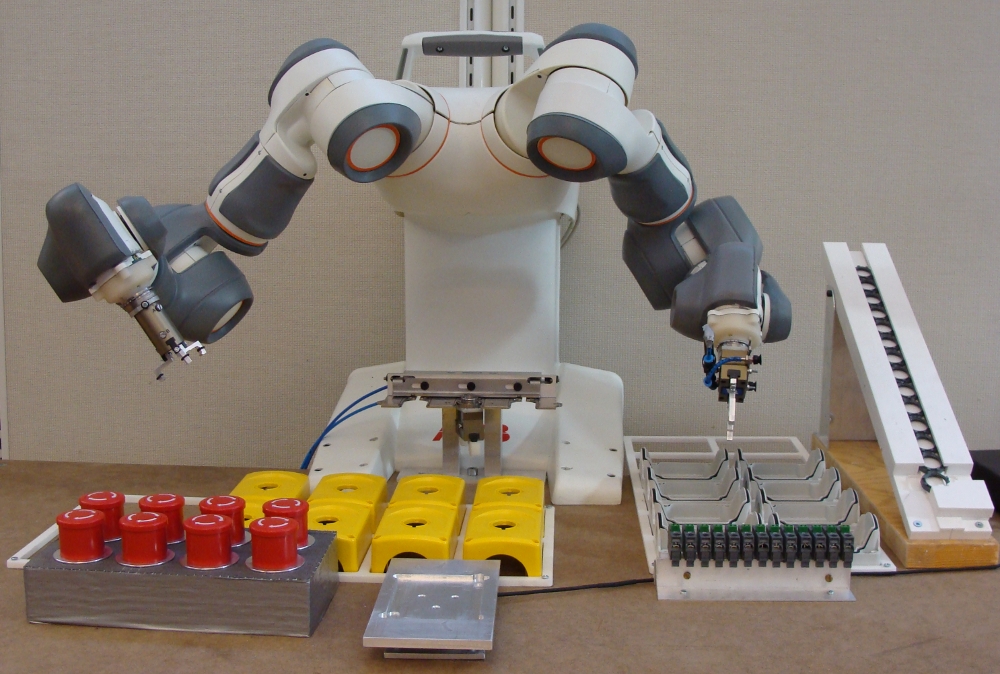

Emergency stop button assembly

The assembly of an emergency stop button was performed using the ABB concept robot FRIDA. A table-mounted force sensor was used for some operations, while estimated forces from the motor torques were used for screwing the nut. The assembly was implemented using both standard position-based control described in RAPID code, and force-controlled parts using the iTaSC framework and the ExtCtrl interface.

Left: The experimental setup for the emergency stop button assembly. Right: Two-handed screwing of nut.

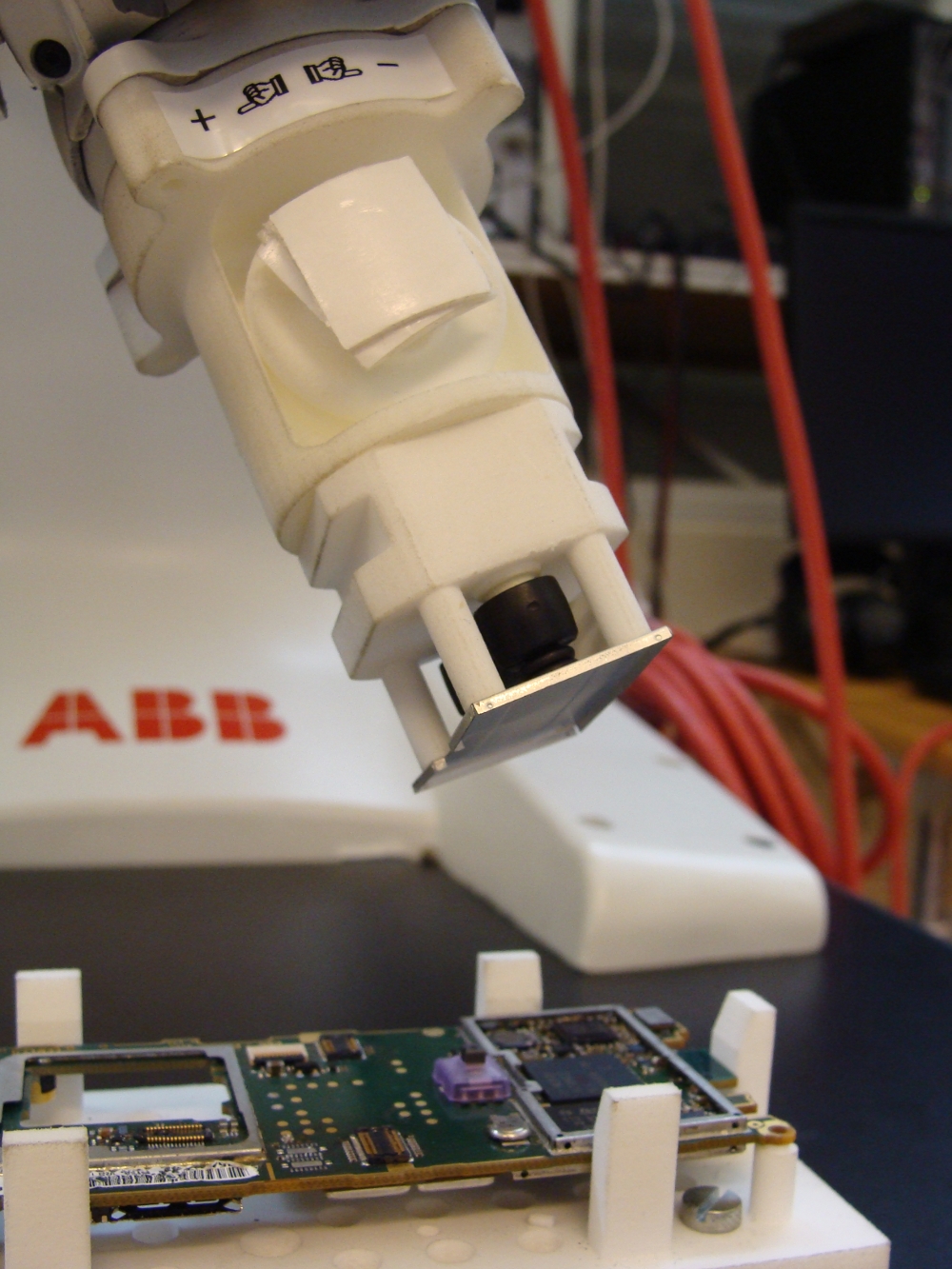

Mobile phone assembly

Another assembly scenario considered was the assembly of a shield can onto a mobile phone PCB (printed circuit board). The assembly was performed as a sequence of guarded search motions. Both forces measured by a force sensor and forces estimated based on the joint control errors were used to accomplish the assembly.

Assembly of the shield can onto the PCB.

Video

- Task-Execution Control: Ball-Catching Robot

External Links

- ABB Concept Robot FRIDA http://www.abb.com/cawp/abbzh254/8657f5e05ede6ac5c1257861002c8ed2.aspx

References

Andreas Stolt, Anders Robertsson, Rolf Johansson: "Robotic Force Estimation using Dithering to Decrease the Low Velocity Friction Uncertainties". In 2015 IEEE International Conference on Robotics and Automation, Seattle, Washington, USA, May 2015.

Magnus Linderoth, Andreas Stolt, Anders Robertsson, Rolf Johansson: "Robotic Force Estimation Using Motor Torques and Modeling of Low Velocity Friction Disturbances". In 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, November 2013.

Nicola Maria Ceriani, Andrea M. Zanchettin, Paolo Rocco, Andreas Stolt, Anders Robertsson: "A constraint-based strategy for task-consistent safe human-robot interaction". In 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, November 2013.

Maj Stenmark, Andreas Stolt: "A System for High-Level Task Specification Using Complex Sensor-Based Skills". In Robotics: Science and Systems (RSS) 2013 Workshop on Programming with Constraints, Berlin, Germany, June 2013.

Magnus Linderoth, Anders Robertsson, Rolf Johansson: "Color-Based Detection Robust to Varying Illumination Spectrum". In IEEE Workshop on Robot Vision (WoRV) 2013, Clearwater Beach, Florida, USA, January 2013.

Andreas Stolt, Magnus Linderoth, Anders Robertsson, Rolf Johansson: "Robotic Assembly of Emergency Stop Buttons". In 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 2013.

Andreas Stolt: "Robotic Assembly and Contact Force Control". Licentiate Thesis ISRN LUTFD2/TFRT--3256--SE, Department of Automatic Control, Lund University, Sweden, December 2012.

Sang Hyoung Lee, Il Hong Suh, Sylvain Calinon, Rolf Johansson: "Learning Basis Skills by Autonomous Segmentation of Humanoid Motion Trajectories". In 12th IEEE-RAS International Conference on Humanoid Robots, Osaka, Japan, November 2012.

Andreas Stolt, Magnus Linderoth, Anders Robertsson, Rolf Johansson: "Robotic Assembly Using a Singularity-Free Orientation Representation Based on Quaternions". In 10th International IFAC Symposium on Robot Control, Dubrovnik, Croatia, September 2012.

Andreas Stolt, Magnus Linderoth, Anders Robertsson, Rolf Johansson: "Adaptation of Force Control Parameters in Robotic Assembly". In 10th International IFAC Symposium on Robot Control, Dubrovnik, Croatia, September 2012.

Andreas Stolt, Magnus Linderoth, Anders Robertsson, Rolf Johansson: "Force Controlled Robotic Assembly without a Force Sensor". In 2012 IEEE International Conference on Robotics and Automation, St. Paul, Minnesota, USA, May 2012.

Magnus Linderoth: "Robotic Work-Space Sensing and Control". Licentiate Thesis ISRN LUTFD2/TFRT--3251--SE, Department of Automatic Control, Lund University, Sweden, June 2011.

Andrea M. Zanchettin, Paolo Rocco, Anders Robertsson, Rolf Johansson: "Exploiting Task Redundancy in Industrial Manipulators during Drilling Operations". In 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, May 2011.

Andreas Stolt, Magnus Linderoth, Anders Robertsson, Rolf Johansson: "Force Controlled Assembly of Emergency Stop Button". In 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, May 2011.

Magnus Linderoth, Kristian Soltesz, Anders Robertsson, Rolf Johansson: "Initialization of the Kalman Filter without Assumptions on the Initial State". In 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, May 2011.

Anders Björkelund, Lisett Edström, Mathias Haage, Jacek Malec, Klas Nilsson, Pierre Nugues, Sven Gestegård Robertz, Denis Störkle, Anders Blomdell, Rolf Johansson, Magnus Linderoth, Anders Nilsson, Anders Robertsson, Andreas Stolt, Herman Bruyninckx: "On the Integration of Skilled Robot Motions for Productivity in Manufacturing". In 2011 IEEE/CIRP International Symposium on Assembly and Manufacturing (ISAM), Tampere, Finland, May 2011.

Rolf Johansson: "Continuous-Time Model Identification and State Estimation Using Non-Uniformly Sampled Data". In Proc. 19th International Symposium on Mathematical Theory of Networks and Systems, July 2010.

Magnus Linderoth, Anders Robertsson, Karl Åström, Rolf Johansson: "Object Tracking with Measurements from Single or Multiple Cameras". In 2010 IEEE International Conference on Robotics and Automation, Anchorage, Alaska, May 2010.

Leonid Freidovich, Anders Robertsson, Anton Shiriaev, Rolf Johansson: "LuGre-Model-Based Friction Compensation". IEEE Transactions on Control Systems Technology, 18:1, pp. 194–200, January 2010.

Rolf Johansson: "Focus on: Subspace-based Identification and Its Applications". International Journal of Adaptive Control and Signal Processing, 23:12, pp. 1051–1052, December 2009.

Rolf Johansson, P. A. Fransson, Måns Magnusson: "Optimal Coordination and Control of Posture and Movements". Journal of Physiology - Paris, 103:3-5, pp. 159–177, October 2009.

Rolf Johansson, Magnus Annerstedt, Anders Robertsson: "Stability of Haptic Obstacle Avoidance and Force Interaction". In 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, St Louis, Missouri, October 2009.

Rolf Johansson, Anders Robertsson: "Stability of Robotic Obstacle Avoidance and Force Interaction". In 9th IFAC International Symposium on Robot Control (SYROCO'09), Gifu, Japan, September 2009.

Magnus Linderoth, Anders Robertsson, Karl Åström, Rolf Johansson: "Vision Based Tracker for Dart-Catching Robot". In 9th IFAC International Symposium on Robot Control (SYROCO'09), Gifu, Japan, September 9-12, 2009, pp. 883-888, September 2009.

2014-03-18