Performance Monitoring and Diagnosis

Researchers: Tore Hägglund

Stiction and backlash in control valves are the major problem at the loop level in process control plants. There are two aspects of the problem. First of all, the nonlinearities deteriorate the control performance. Secondly, the loops facing these problems often remain undiscovered by the personnel in process control plants. These are the motives for research in the area of automatic performance monitoring and diagnosis.

Backlash estimation

A new method for detection and estimation of backlash in control loops has been developed. The detection procedure is based on normal operating data. It is not assumed that the output from the backlash is measured. The procedure is automatic in the sense that no information has to be provided from the user to run the procedure. Since an estimate of the dead band caused by the backlash is provided by the procedure, the procedure gives all information needed to compensate for the backlash. The procedure has been tested in industry and a MS project has been performed in collaboration with ABB to prepare for implementation in an industrial DCS system. The method is patented.

Valve Stiction Diagnosis

Valves with a high level of static friction (stiction) generates stick-slip motion that causes the control loops to oscillate. There are several efficient methods for automatic oscillation detection available. There may, however, be several causes of oscillations in control loops. Besides sticky valves, bad controller tuning and external load disturbances may cause oscillations. Therefore, there is an interest in procedures for automatic diagnosis of oscillations.

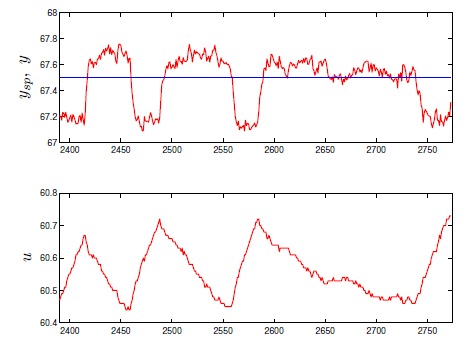

In this project, a method for automatic diagnosis of stiction in control valves has been derived. The diagnosis is performed using a shape analysis of the wave form of the oscillations that appear in the process output. In case of stick-slip motion, a rectangular form is obtained, whereas external load disturbances and bad controller tuning gives a sinusoidal wave form. The procedure is automatic in the sense that no process information is assumed except the one that is already available in the controllers. The procedure can be used both on line and off line. It has been tested on industrial data with good results.

Stick-slip motion in a recirculation flow loop in a distillation column

Publications

Tore Hägglund: "A shape-analysis approach for diagnosis of stiction in control valves". Control Engineering Practice, 19:8, pp. 782–789, August 2011.

Tore Hägglund: "Automatic On-Line Estimation of Backlash in Control Loops". Journal of Process Control, 17, pp. 489–499,2007.

Ari Ingimundarson, Tore Hägglund: "Closed-Loop Performance Monitoring Using Loop Tuning". Journal of Process Control, 15:2, pp. 127–133,2005.

Tore Hägglund: "Industrial Implementation of On-line Performance Monitoring Tools". Control Engineering Practice, 13, pp. 1383–1390,2005.

Mikael Petersson, Karl-Erik Årzén, Tore Hägglund: "A comparison of two feedforward control structure assessment methods". International Journal of Adaptive Control and Signal Processing, 17:7--9, pp. 609–624, August 2003.

Ari Ingimundarson, Tore Hägglund: "Performance comparison between PID and dead-time compensating controllers". Journal of Process Control, 12, pp. 887–895,2002.

2013-01-16